Product

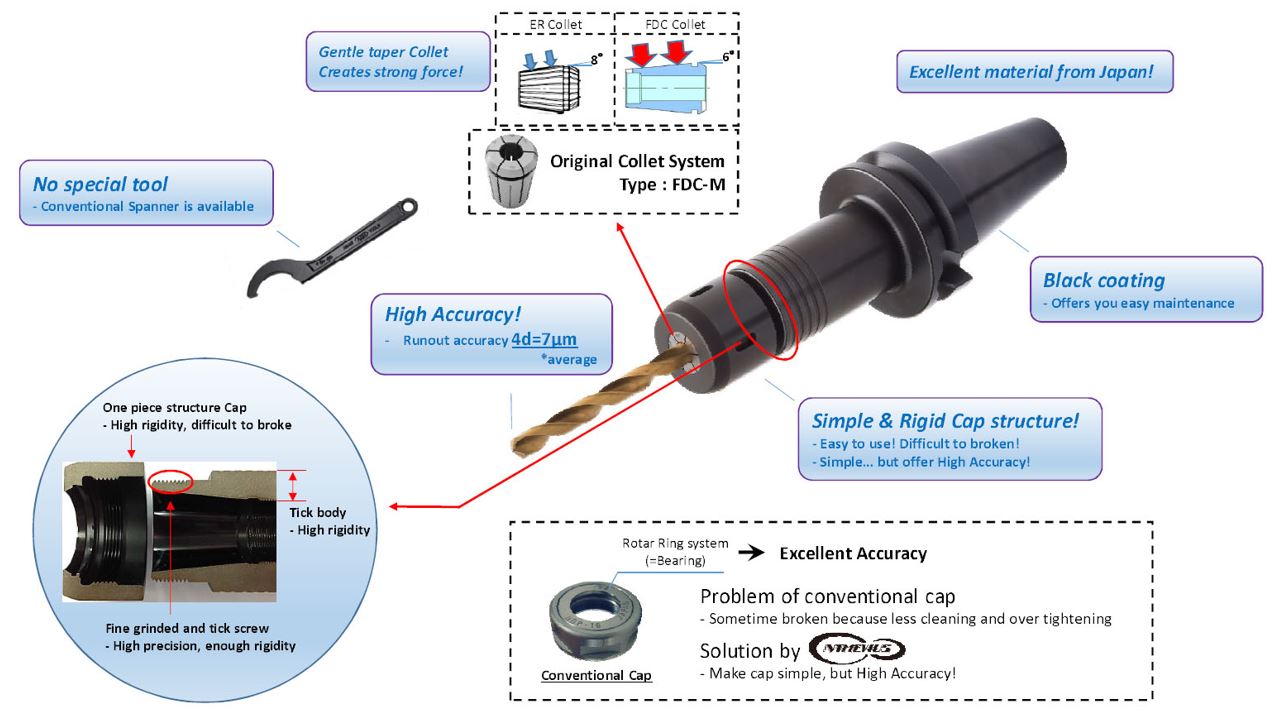

What’s NT MEVIUS series ?

NTMEVIUS Series is tooling developed reflecting the needs from Asian market. Manufactured by NT TOOL (THAILAND) Co.,Ltd. under the strict QC system of NT TOOL CORPORATION in Japan.

What’s NT MEVIUS series ?

User friendly !

- Sometime broken because less

cleaning and over tightening

- Cap is often broken because of

less cleaning and over tightening.

- High rigidity difficult to broke

with enough

rigidity & accuracy

Fine grinded and tick screw

- High precision, enough rigidity

The holder body is entirely blackoxide coated.

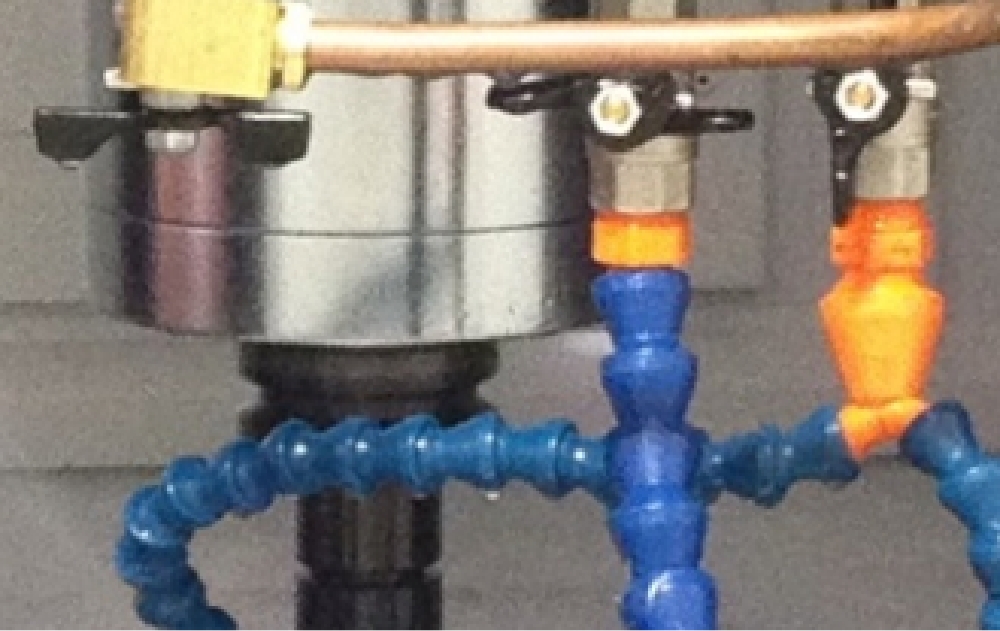

Internal coolant feeding is possible by replacing the collet with FDC-OH or FDC-C type collet.

For cutting tool with oil hole

For cutting tool with oil hole

High accuracy !

Thanks to our original Collet system FDC-M,

NTMEVIUS can offer high accuracy and strong clamping torque.

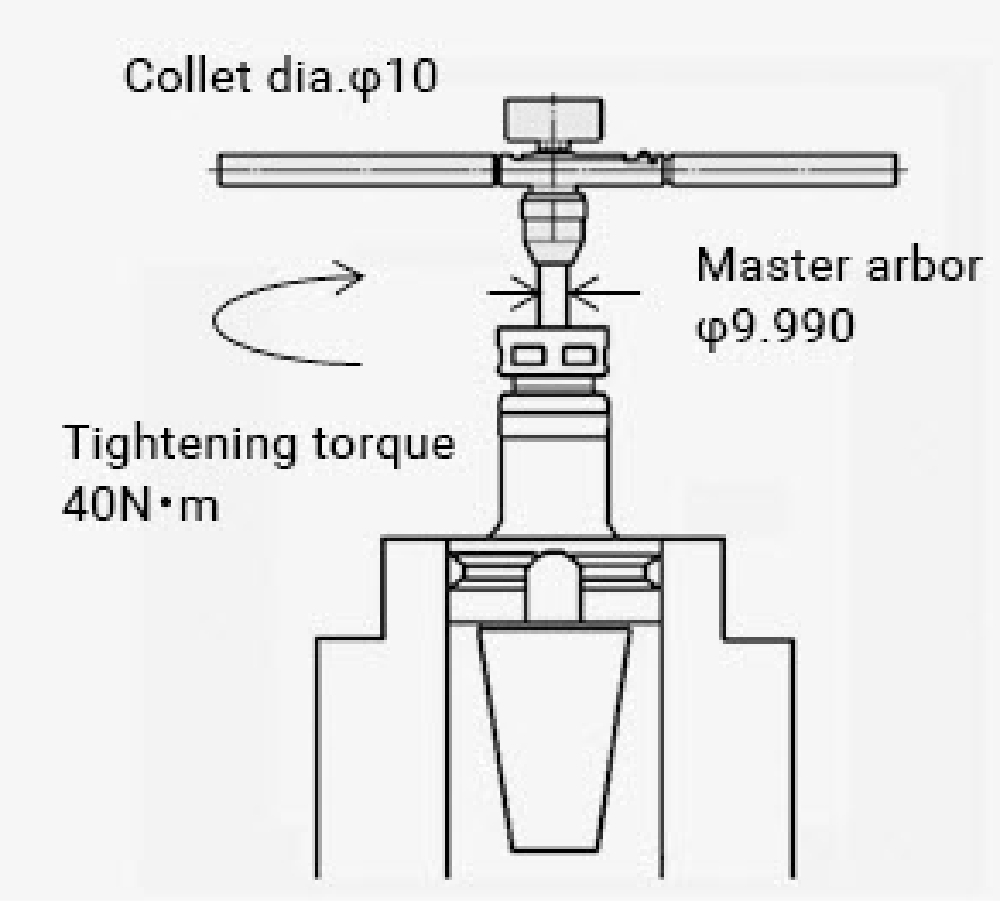

Technical data – Chucking torque

Comparison chucking torque (MDC12 vs ER20)

HOW TO EVALUATE

Measure slip torque with Master arbor

| CHUCKING TORQUE WITH ER COLLET (N・M) | ||||

|---|---|---|---|---|

| Brand | 1 | 2 | 2 | Ave |

| Company A (EURO) BT30/ER20×050 | 35 | 40 | 35 | 36.7 |

| Company B (Asia) BT30-ER20-60 | 30 | 35 | 30 | 31.7 |

| Company C (Asia) BT30-ER20-70 | 35 | 35 | 35 | 35.0 |

| Company D (Asia) BT30-SKA13-90 | 30 | 30 | 35 | 31.7 |

| CHUCKING TORQUE WITH ER COLLET (N・M) | ||||

|---|---|---|---|---|

| Brand | 1 | 2 | 2 | Ave |

| NT MEVIUS BT30-MDC12-90 | 45 | 45 | 45 | 45.0 |

NTMEVIUS IS 20~30% STRONGER THAN ER COLLET !!

Technical data – High balance

Comparison of unbalance value

| CHUCKING TORQUE WITH ER COLLET (N・M) | ||

|---|---|---|

| NTMEVIUS BT30-MDC12-90 | 1.484g・mm~2.451g・mm | O |

| Company A (EURO) BT30/ER20×050 | 1.04g・mm~2.04g・mm | O |

| Company B (Asia) BT30-ER20-60 | 4.70g・mm~7.04g・mm | x |

| Company C (Asia) BT30-ER20-70 | 3.36g・mm~6.63g・mm | x |

| Company D (Asia) BT30-SKA13-90 | 1.20g・mm~3.64g・mm | O |

■ NTMEVIUS CAN BE ROTATED UP TO 20,000RPM !

Note

- G grade will be changed according to rotational speed.

- Unbalance value may be changed depend on size, but NTMEVIUS can be used up to 20,000min-1

CUTTING EXAMPLE

CUTTING EXAMPLE

■ Semi-finishing process

■ Finishing process

■ Cutting condition (Finishing process)

■ Before

– Shorten cycle time

■ After

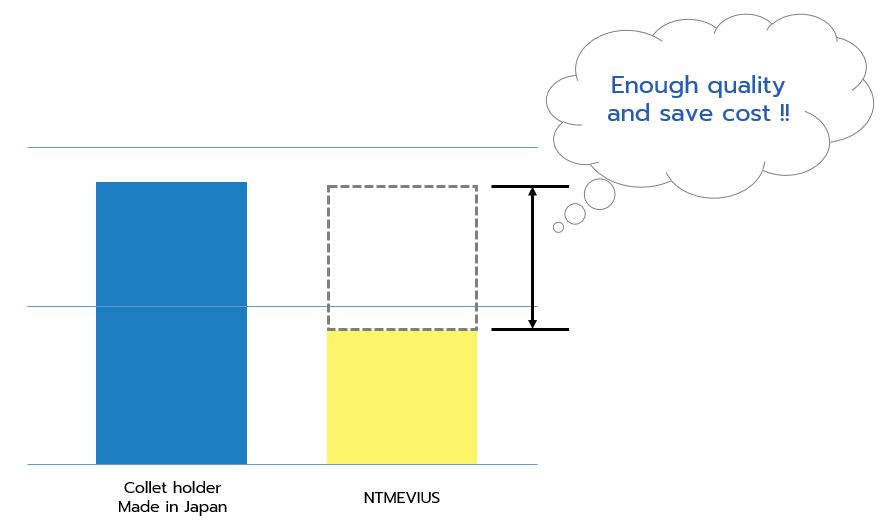

Good Value for Money

Review of features