Product

Customizable software to fit your needs! Increases productivity in the field! Please contact NT TOOL for details.

Max Measurement

- Contactless measurement does not damage cutting edges.

- Easy operation reduces human error.

- Mechanical clamp system with stable repeatability.

- Tightening of a collet holder is possible on the presetter. ( Up to 60Nm )

CONTACTLESS OPTICAL TOOL PRESETTER AEGIS-I SERIES

Options

1

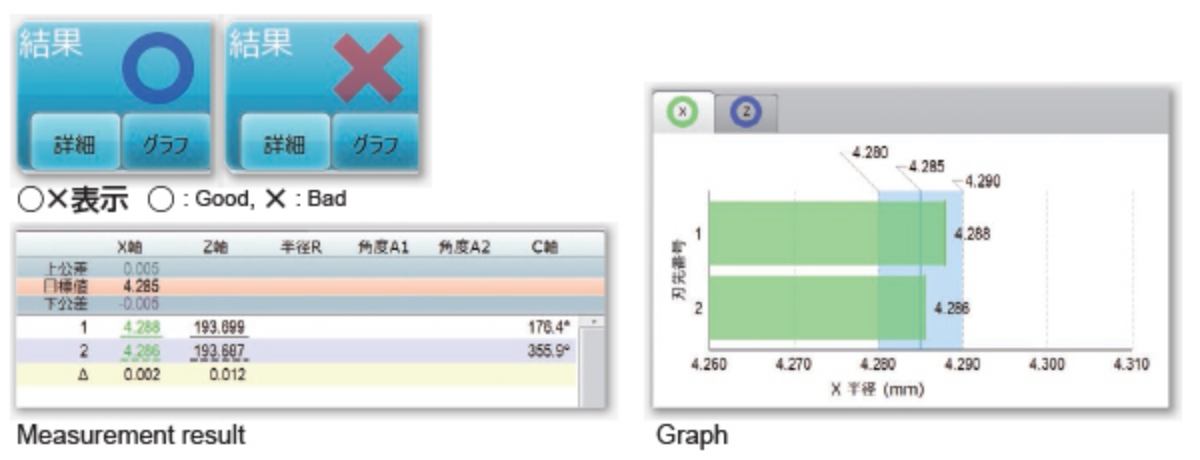

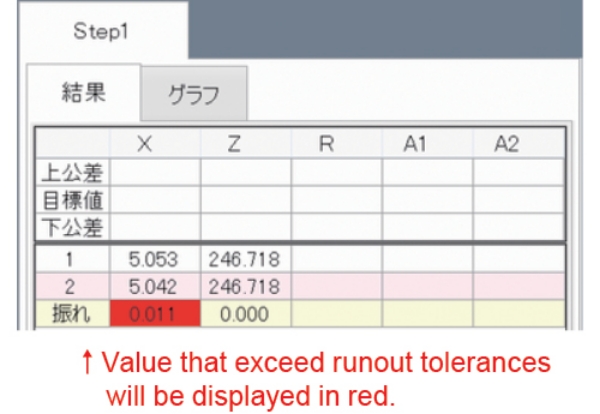

Stop Measurement When Runout Exceeds Tolerances

For multi-step measurements, the measurement will stop if runout exceeds the specified tolerances during the runout measurement step. This prevents measurements from running to completion with unacceptable runout.

2

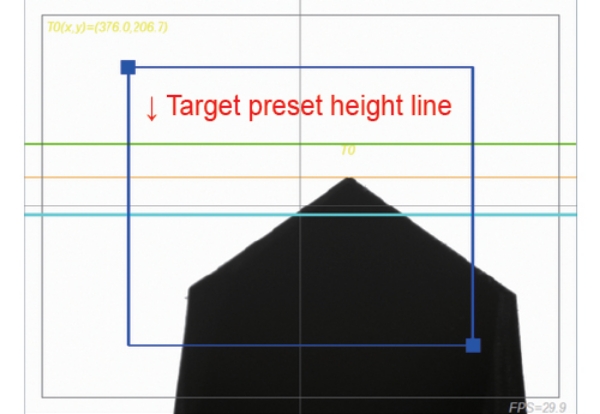

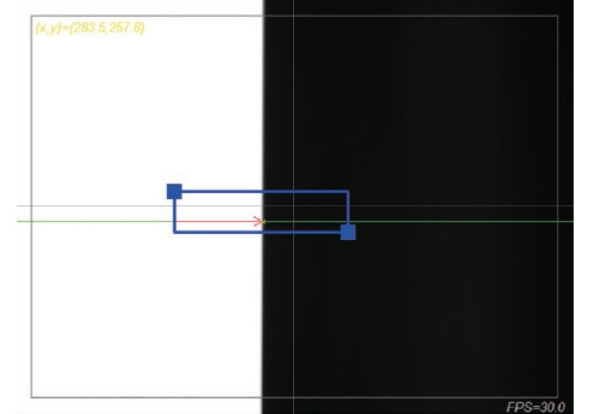

Target Value Input

In “Adjustable Mode,” the target preset height is displayed on the screen with a green line. Use to offset for cap compression when using collet holders, etc.

3

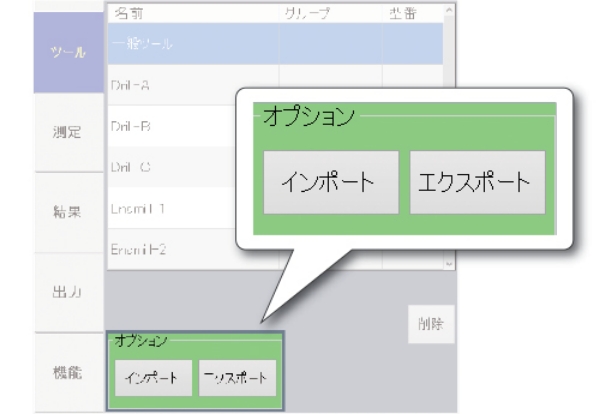

Import, Export

Tool data is imported and exported in the CSV file format. Use to move data to other equipment, or to synchronize tool data between multiple presetters.

4

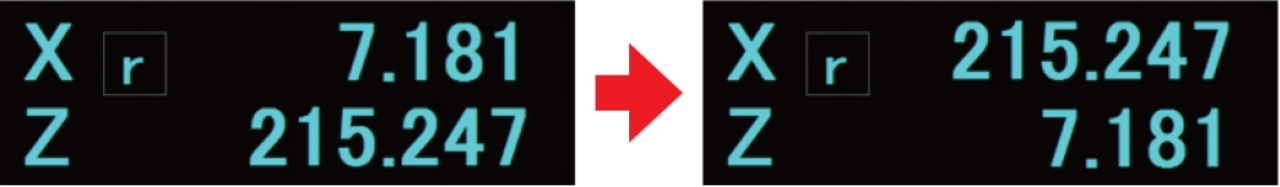

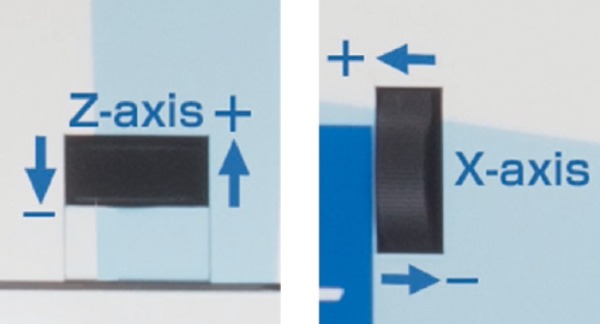

Switch the X-axis and Z-axis

Switch the Z-axis so it displays radial measurements instead of vertical, and the X-axis so it shows vertical measurements instead of radial. Use when machining with lathes, etc., in a non-standard direction.

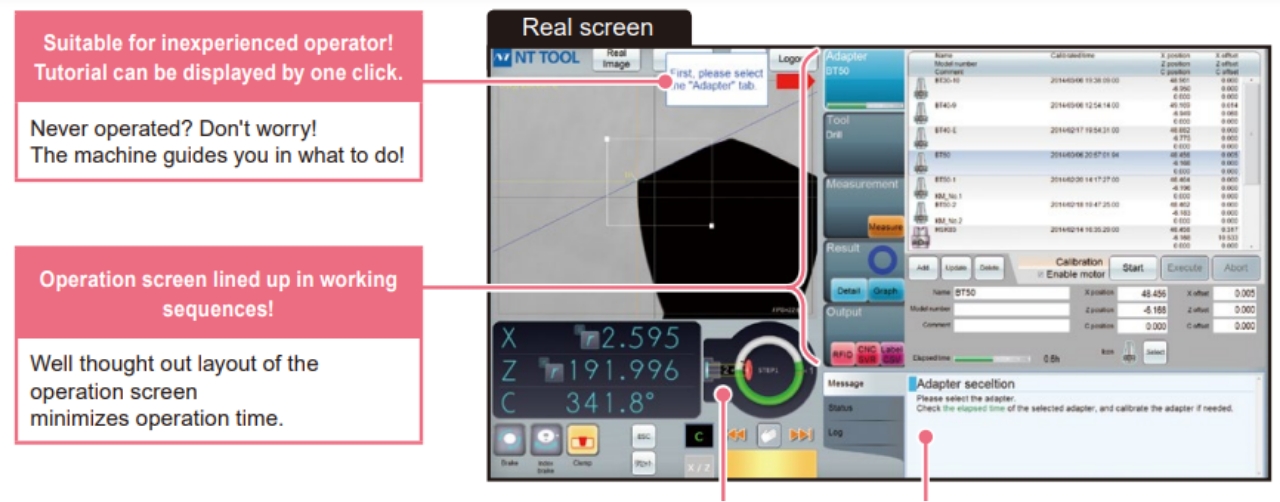

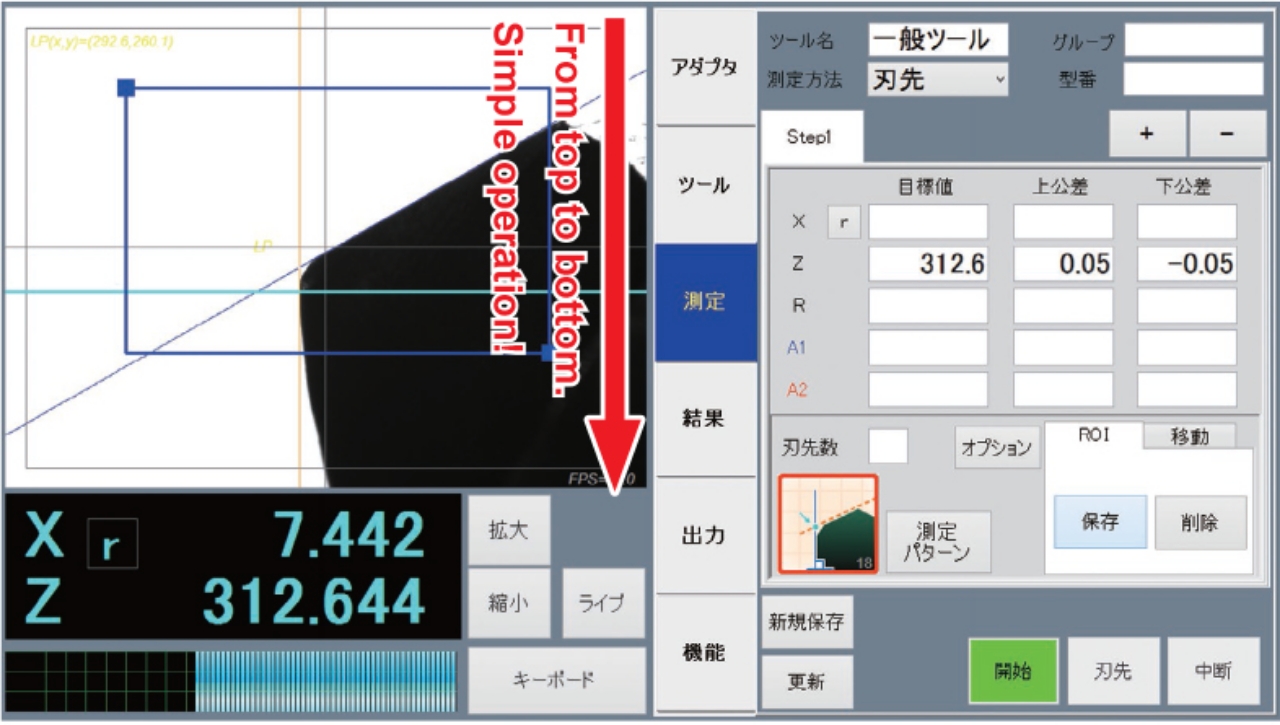

Easy-to-use Software with Tutorial Function

Operation screen lined up in working sequences! Quick operation by switching tabs. Well-thought-out layout of the operation screen minimizes operation time.

Measurement functions

1

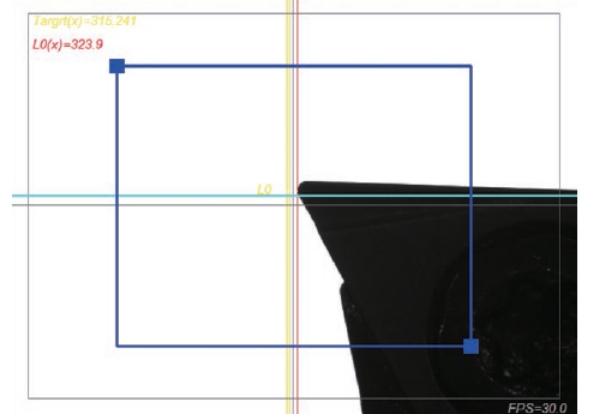

Drill Shoulder Measurement

Results that passed or failed to meet the target values can be displayed in a list, or notified with a sound. Results may also be displayed as a graph.

2

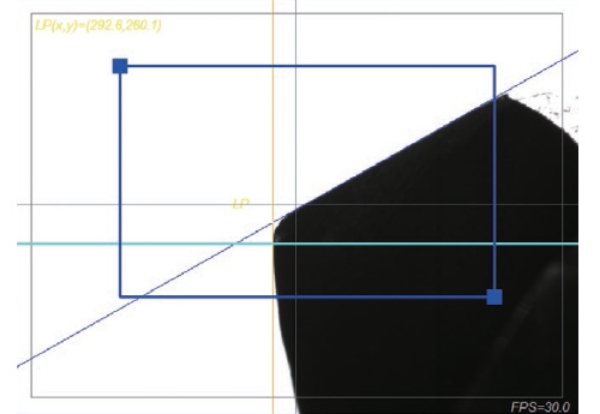

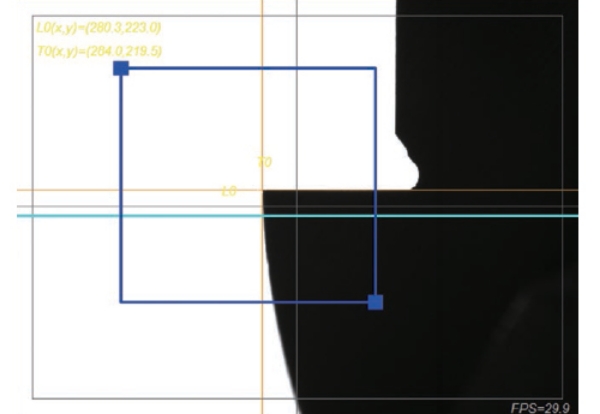

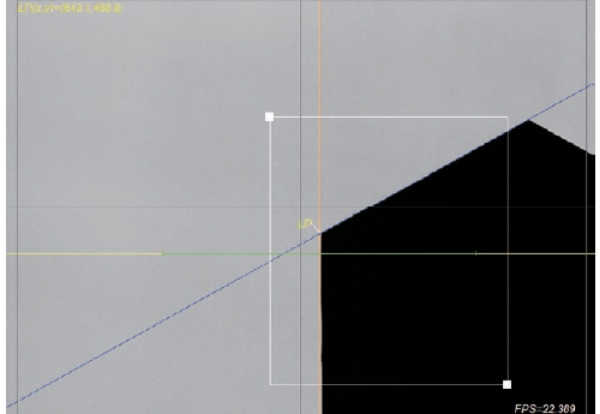

Runout Measurement of the Cutting Edge

Capture the area you want to measure. Then, turn the spindle 360degrees.

3

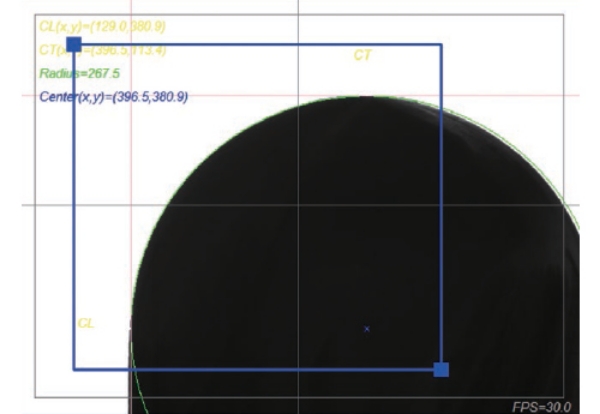

Measuring Afterimage

The cutting tool’ s profile is plotted by rotating the spindle 360 degrees.

4

Special Tolerance

Easy diameter adjustment for boring bars with presetting target shown on the screen.

5

Measuring Step Drill

Each step can be measured separately.

6

Real Image of Cutting Edge

Wearing and chipping on cutting edge can be inspected.

CONTACTLESS OPTICAL TOOL PRESETTER AEGIS-I SERIES

User Friendly Mechanical Body

■ Camera Handle

Simple one hand operation. Movable in X-axis direction or Z-axis direction separately/simultaneously.

■ Fine Adjustment Dial for Z-axis / X-axis

Quick camera positioning by rotating the dial.

■ Camera Arm

Measurement up to dia.400mm is possible.

■ Tightening of a collet holder is possible. (Up to 60Nm)

Move away the camera from the spindle when tightening. Adjustment of cutting tool projection length and runout measurement / adjustment can be done in one spot.

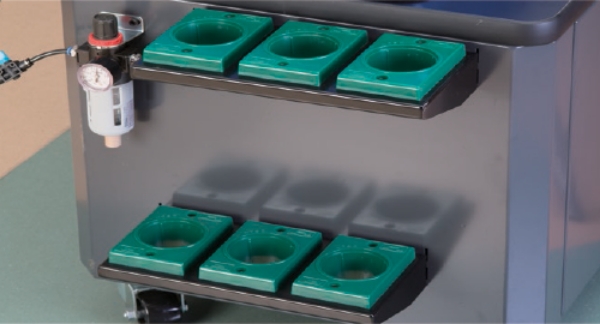

■ Adapter Tray Equipped

Frequently used adapters and holders can be placed nearby.

■ Cutting Tool Projection Length Adjustment (Option)

An operation handle for cutting tool projection length adjustment can be added.

■ Mechanical Clamp

400kg air cylinder fi rmly clamps the tool holder. Good repetitive accuracy of tool holder clamping/unclamping.

■ Motor driven spindle

The rotation of the spindle can be automated.

Easy-to-use Software with Tutorial Function.

Basic Function

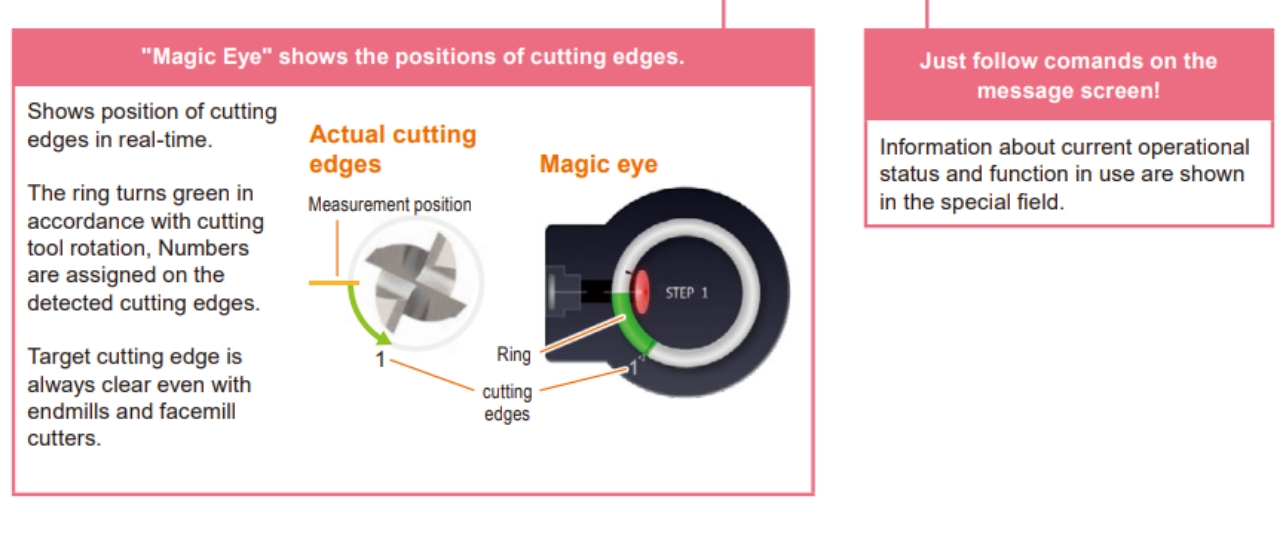

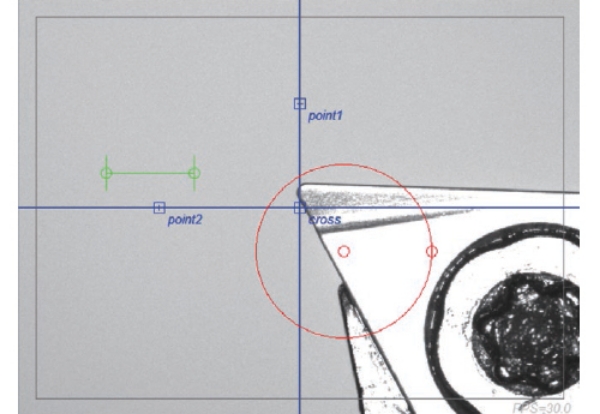

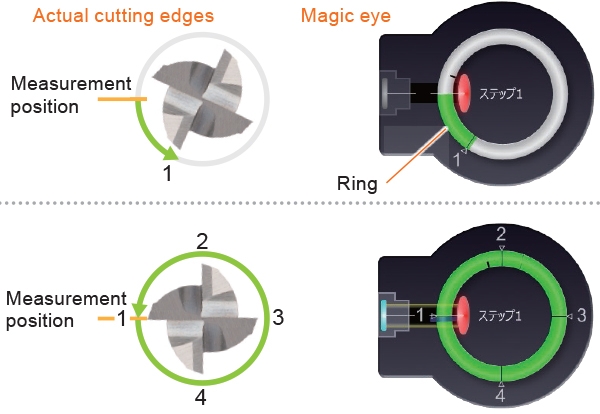

■ “Magic Eye” shows the positions of cutting edges.

Target cutting edge is always clear even with endmills and facemill cutters.

■ Beginning of measurement

The ring turns green in accordance with cutting tool rotation. Numbers are assigned on the detected cutting edges.

■ Detection of cutting edges completed.

Shows position of cutting edges in real-time.

■ Runout measurement of the cutting edge

Capture the area where you want to measure. Then, turn the spindle 360degrees.

The measurement result against target value can be shown in×along with sound eff ects. The result can be also shown as a graph.